Have you ever seen the term OEM on car parts, electronics, or software and wondered what it actually means? OEM stands for Original Equipment Manufacturer, a term used to describe products made by the original producer rather than a third-party or aftermarket company.

If you’re buying a new laptop, upgrading your PC, or replacing a car part, understanding OEM products can help you make smarter choices.

OEM items are often associated with higher quality, perfect compatibility, and manufacturer warranties, but they can also come at a higher price compared to aftermarket alternatives.

In this article, we’ll explore what OEM really means, where it’s commonly used, the differences between OEM and aftermarket products, how to identify OEM items, and the pros and cons of choosing them.

By the end, you’ll have a clear understanding of OEM and be better equipped to make informed purchasing decisions.

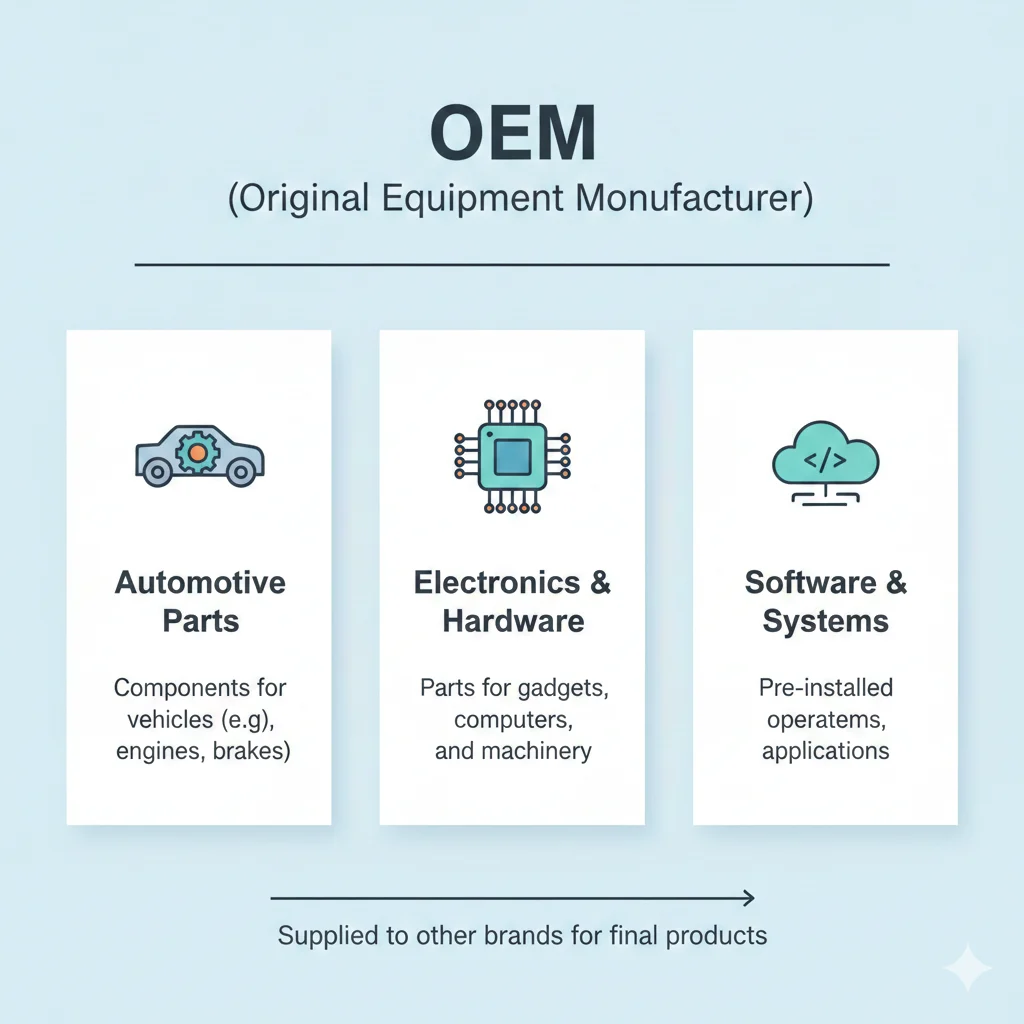

OEM Meaning and Definition

The term OEM stands for Original Equipment Manufacturer, and it refers to the company that originally designs and produces a product or its components. In simple terms, an OEM is the “original maker” of a product before it reaches the market or before other companies create compatible versions.

For example, if you buy a computer, the manufacturer that produces the processor or graphics card is considered the OEM, while other brands may assemble or resell the product under their name.

OEM products are widely used across multiple industries, including automotive, electronics, and software. In the automotive world, OEM parts are made by the car manufacturer or a contracted company to meet exact specifications, ensuring compatibility and reliability.

In technology, OEM software or hardware is pre-installed on devices like laptops and smartphones.

Understanding the meaning of OEM helps consumers distinguish between original products and aftermarket or third-party alternatives, ensuring informed choices when quality, warranty, and performance matter most.

OEM vs Aftermarket: Key Differences

When choosing products like car parts, electronics, or software, you’ll often hear the terms OEM and aftermarket. While both serve similar purposes, they have distinct differences that can affect quality, compatibility, and cost.

OEM products are made by the original manufacturer and are designed to meet the exact specifications of the original item. This ensures perfect fit, reliability, and warranty coverage.

For example, an OEM car brake pad is built to match the original performance and safety standards of your vehicle. Similarly, OEM software pre-installed on a laptop comes directly from the original developer and is fully supported.

Aftermarket products, on the other hand, are made by third-party companies and are often designed to be compatible with a range of brands or models.

While aftermarket options can be more affordable and offer customization, they may vary in quality and may not always match the performance of OEM products.

Choosing between OEM and aftermarket depends on your priorities: if you value guaranteed quality and compatibility, OEM is usually the safer choice; if cost or customization is more important, aftermarket options can be a viable alternative.

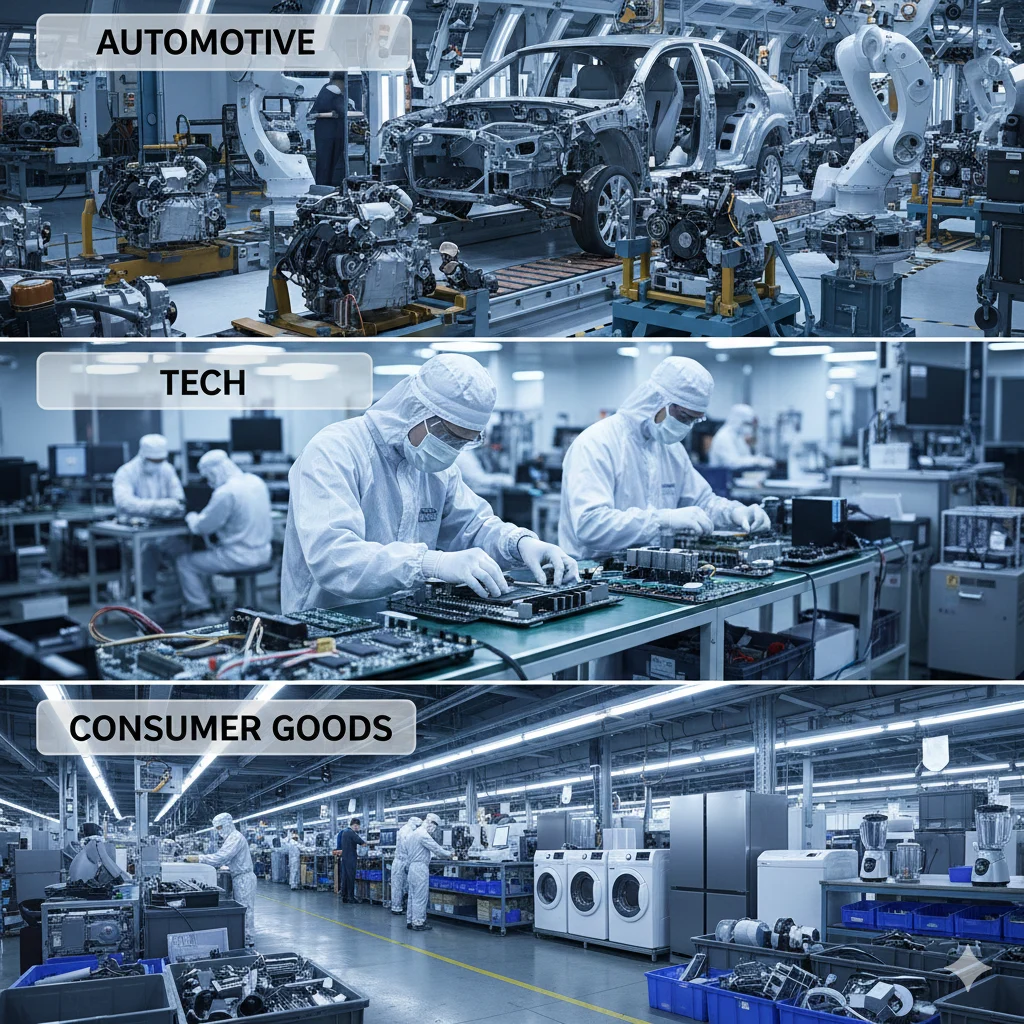

Common Industries Where OEM is Used

OEM products are found in a wide range of industries, from automotive to technology and consumer goods. Understanding where OEM is used helps consumers make informed choices about quality, compatibility, and value.

1. Automotive Industry:

OEM parts are widely used in cars, trucks, and motorcycles. Components like engines, tires, brakes, and electronics are often supplied by the original manufacturer to ensure proper fit and performance. Using OEM parts in vehicles guarantees safety, reliability, and warranty coverage.

2. Technology and Electronics:

In the tech world, OEM products include computer components, graphics cards, processors, and pre-installed software. For example, a laptop may come with an OEM version of Windows or other software, which is supported by the manufacturer. OEM components are preferred by PC builders and gamers for compatibility and performance.

3. Manufacturing and Consumer Goods:

OEM is also common in appliances, machinery, and other consumer products. Companies may produce parts that are sold under another brand name, ensuring quality and consistency.

Across all these industries, OEM products are valued for reliability, precision, and support, making them a popular choice for consumers who want products that meet original specifications.

Advantages of OEM Products

Choosing OEM products comes with several advantages that make them a preferred choice for many consumers and businesses.

1. Guaranteed Quality: OEM products are manufactured to meet the exact standards of the original design, ensuring consistent performance and reliability. This is particularly important in industries like automotive or electronics, where precision is critical.

2. Perfect Compatibility: Because OEM parts are made by the original manufacturer, they are designed to fit perfectly with the existing system or device. For example, an OEM car part or laptop component works seamlessly without modifications.

3. Warranty Coverage: OEM products often come with manufacturer warranties, providing peace of mind and protection against defects. This can be especially valuable when investing in expensive electronics or vehicle components.

4. Better Performance: OEM components are built to the original specifications, meaning they often outperform aftermarket or generic alternatives in longevity and efficiency.

5. Reduced Risk of Issues: Using OEM products lowers the risk of compatibility problems, malfunction, or failure, ensuring that your device, vehicle, or system continues to function optimally.

In short, OEM products offer reliability, performance, and peace of mind, making them a worthwhile investment when quality matters.

Disadvantages of OEM Products

While OEM products offer reliability and quality, they also come with certain disadvantages that consumers should consider before purchasing.

1. Higher Cost: OEM products are often more expensive than aftermarket or generic alternatives. This higher price reflects the original manufacturer’s quality standards and warranty coverage. For some consumers, especially those on a budget, this can be a significant drawback.

2. Limited Availability: Not all OEM parts or products are readily available in stores. In some cases, you may need to order directly from the manufacturer, which can take more time and may not be convenient.

3. Less Customization: OEM products are designed to meet the original specifications, leaving little room for modification or personalization. In contrast, aftermarket alternatives often offer more flexibility for custom features or designs.

4. Replacement Delays: Since OEM items are specific to certain models or systems, replacement parts may take longer to arrive compared to widely available aftermarket options.

5. Perceived Overkill for Some Users: For casual consumers, the superior quality of OEM products may not always justify the extra cost, especially for items that don’t require perfect compatibility or long-term durability.

While OEM products are ideal for reliability and performance, it’s important to weigh these disadvantages against your budget, timeline, and needs.

How to Identify OEM Products

Knowing how to identify OEM products is essential to ensure you’re getting genuine, high-quality items rather than aftermarket or counterfeit alternatives.

1. Check the Packaging: OEM products often come in branded packaging from the original manufacturer. Look for logos, holograms, and official seals that indicate authenticity.

2. Product Labeling: OEM items are usually labeled clearly with the manufacturer’s name, model number, and part number. This is especially important for electronics, car parts, and software.

3. Serial Numbers and Certifications: Many OEM products include unique serial numbers or certification labels. These numbers can often be verified on the manufacturer’s official website to confirm legitimacy.

4. Authorized Sellers: Purchase OEM products from authorized retailers or directly from the manufacturer. Buying from unofficial sources increases the risk of counterfeit or substandard items.

5. Documentation and Warranty: OEM products often include manuals, warranty cards, or other documentation from the original manufacturer. Lack of official paperwork can be a warning sign.

By following these steps, you can confidently identify OEM products, ensuring quality, reliability, and proper warranty coverage for your purchases.

OEM in Software and Tech Products

In the world of technology, OEM has a special role, particularly when it comes to software and computer hardware. OEM software is pre-installed on devices such as laptops, desktops, and smartphones by the manufacturer. For example, a laptop may come with an OEM version of Windows, which is licensed specifically for that device and often tied to its hardware.

OEM hardware includes components like processors, graphics cards, and motherboards that are built by the original manufacturer for integration into branded devices. These components are designed to work seamlessly with the system, ensuring optimal performance and compatibility.

One key difference between OEM software and retail software is support. OEM software is generally supported by the device manufacturer rather than the software company directly, meaning updates and technical assistance may differ from retail versions. Similarly, OEM hardware often comes with warranties managed by the original device maker rather than third-party sellers.

Understanding OEM in tech helps consumers, PC builders, and businesses make informed decisions when purchasing devices or software, balancing cost, compatibility, and long-term support.

Common OEM Questions and Misconceptions

Many people are familiar with the term OEM but often have questions or misconceptions about its meaning, uses, and value. Clarifying these points can help consumers make informed decisions.

1. Is OEM Better Than Aftermarket?

OEM products are typically more reliable and compatible since they are made by the original manufacturer. Aftermarket options may be cheaper and offer customization but can vary in quality.

2. Can OEM Parts Be Used in Refurbished Products?

Yes, OEM parts can be used in refurbished devices or vehicles, but it’s important to ensure proper compatibility and maintain warranty coverage.

3. Do OEM Warranties Differ from Retail Warranties?

OEM warranties are usually provided by the original manufacturer and may differ in coverage and duration compared to retail warranties. Always check the warranty terms before purchasing.

4. Are OEM Products Always Expensive?

OEM items often cost more due to guaranteed quality and brand reliability, but the long-term benefits can outweigh the initial expense.

5. Is OEM Only for Cars and Electronics?

No. OEM applies to many industries, including software, machinery, consumer goods, and even medical devices.

By understanding these common questions, you can better evaluate whether OEM products are right for your needs.

Tips for Choosing OEM Products

Choosing OEM products wisely can save you money, ensure compatibility, and guarantee quality. Here are some practical tips to help you make the right decision:

1. Verify Compatibility: Always check that the OEM product is designed for your specific device, vehicle, or system. Using the wrong part can cause malfunctions or void warranties.

2. Compare Prices: While OEM products are usually more expensive, compare prices from authorized retailers and the manufacturer to ensure you’re getting a fair deal.

3. Check Authenticity: Look for official logos, serial numbers, certification labels, and original packaging to confirm that the product is genuine. Avoid unofficial sellers that may offer counterfeit items.

4. Consider Warranty and Support: OEM products often come with warranties provided by the original manufacturer. Make sure you understand the coverage, duration, and support options.

5. Evaluate Your Needs: Determine whether OEM is necessary for your situation. If high quality and guaranteed compatibility are essential, OEM is the best choice. For non-critical items or budget options, aftermarket products may suffice.

By following these tips, you can confidently select OEM products that meet your requirements while avoiding potential pitfalls.

Is OEM the Same as Original?

OEM is not always the same as “original,” even though the two terms are closely related. OEM refers to the manufacturer that produces parts or products used in another company’s final item. An “original” product usually means the one sold directly under the brand name you recognize.

For example, a car manufacturer may sell a brake pad under its own brand. That brake pad might actually be made by another company—the OEM. The OEM version and the branded version may be identical in quality, but the branding and packaging are different.

So while OEM products are often original in design and quality, they may not carry the original brand’s logo. This is why OEM parts are sometimes cheaper, even though they are made by the same manufacturer that supplies the brand.

What Is Meant by an OEM Company?

An OEM company is a business that manufactures products or components that are used by another company to create a finished product. The OEM usually does not sell directly to consumers under its own name.

For example, a company might manufacture laptop keyboards, engines, sensors, or software. Another brand then assembles those parts into a complete product and sells it under its own brand name. The part-maker is the OEM.

OEM companies play a key role in global manufacturing because they specialize in specific components. This allows brands to focus on design, marketing, and customer experience while relying on OEMs for production expertise.

In short, an OEM company is a behind-the-scenes manufacturer that helps other brands bring products to market.

Is OEM Close to Original?

Yes, OEM products are usually very close to original, and in many cases, they are exactly the same. The main difference is branding and packaging, not quality or design.

OEM products are often made using the same materials, machinery, and specifications as branded products. The reason they may cost less is that they don’t include branding, marketing costs, or retail packaging.

However, “close to original” doesn’t mean identical in every situation. Some OEM products may be produced to slightly different specifications based on the buyer’s requirements.

Overall, OEM products are generally considered reliable, compatible, and high-quality—especially when purchased from authorized sellers.

Is BMW an OEM?

Yes, BMW is an OEM, but the term applies differently depending on context. BMW is an OEM because it manufactures vehicles and original parts used in its cars. At the same time, BMW also relies on other OEM companies to supply components like electronics, brakes, and sensors.

For example, BMW may design a braking system, but the actual brake components could be manufactured by a specialized OEM supplier. BMW then installs those parts and sells the finished vehicle under its brand.

So BMW can be both:

- An OEM (for its vehicles and branded parts)

- A buyer of OEM parts from other manufacturers

This is very common in the automotive industry.

What Does OEM Stand For in Business?

In business, OEM stands for Original Equipment Manufacturer and refers to companies that produce goods used by other businesses in their final products.

OEM relationships are common in industries like electronics, automotive, software, and manufacturing. One company focuses on production, while the other focuses on branding, sales, and distribution.

For example, a tech company may design a product but outsource manufacturing to an OEM. The OEM produces the item, and the brand sells it under its own name.

In business terms, OEM agreements help reduce costs, improve efficiency, and speed up production while maintaining quality standards.

Does OEM Mean Original?

OEM does not automatically mean original, but it often means original manufacturer. This is where confusion happens.

OEM means the product comes from the same manufacturer that supplies the original brand. However, it may not be sold by the brand itself. That’s why OEM products may not include logos, retail packaging, or full warranties.

So:

- OEM = made by the original manufacturer

- Original = sold by the brand under its name

OEM products are usually authentic and reliable, but “original” refers more to branding than manufacturing.

OEM Meaning in Sales

In sales, OEM refers to products or components sold to another company, not directly to consumers. OEM sales focus on bulk orders, long-term contracts, and business-to-business relationships.

For example, a manufacturer might sell thousands of components to a brand that assembles and resells them. This is considered OEM sales.

OEM sales typically involve:

- Lower per-unit pricing

- Large volume orders

- Custom specifications

- Long-term partnerships

OEM sales are different from retail sales, which target individual consumers.

What Is OEM in Automotive?

In the automotive industry, OEM refers to parts made by the same manufacturer that supplies the car brand. OEM car parts are designed to fit and function exactly like the original factory-installed parts.

Examples include:

- OEM brake pads

- OEM filters

- OEM sensors

- OEM body parts

OEM parts are often more expensive than aftermarket parts but are known for compatibility and reliability. Many car owners choose OEM parts for repairs to maintain performance, safety, and warranty compliance.

OEM Meaning in Computer

In computers, OEM refers to hardware or software preinstalled by the manufacturer. Common examples include OEM versions of Windows, drivers, and system components.

An OEM Windows license, for example, comes preinstalled on a computer and is tied to that specific device. It’s usually cheaper than a retail license but cannot be transferred to another computer.

OEM computer parts include:

- Motherboards

- Power supplies

- Hard drives

- Prebuilt system components

OEM in computing focuses on system integration rather than individual retail sales.

What Does OEM Stand For in Medical?

In the medical field, OEM stands for Original Equipment Manufacturer and refers to companies that produce medical devices or components used by hospitals and healthcare brands.

OEM medical products include:

- Diagnostic equipment

- Surgical instruments

- Imaging devices

- Medical sensors

Medical OEMs must follow strict regulations and quality standards. Hospitals may purchase equipment directly from OEMs or through branded suppliers.

OEM manufacturing is essential in healthcare because it ensures precision, safety, and consistency in medical devices.

What Does OEM Stand For in Emergency Management?

In emergency management, OEM commonly stands for Office of Emergency Management, not Original Equipment Manufacturer.

This OEM refers to government or municipal agencies responsible for:

- Disaster preparedness

- Emergency response coordination

- Public safety planning

- Crisis management

For example, a city’s OEM may handle responses to floods, earthquakes, or public emergencies. This meaning is context-specific and completely different from manufacturing-related OEM.

Understanding the context is important to avoid confusion.

What Does OEM Stand For in Construction?

In construction, OEM usually means Original Equipment Manufacturer, referring to companies that make construction machinery, tools, or components.

Examples include:

- Heavy equipment manufacturers

- Tool producers

- Machinery component suppliers

OEM construction equipment parts are designed specifically for machines like excavators, cranes, and loaders. Contractors often choose OEM parts for durability, safety, and proper fit.

OEMs play a vital role in construction by ensuring equipment reliability and compliance with industry standards.

What Does OEM Stand For in Manufacturing

In manufacturing, OEM refers to a company that produces components or products that are then branded and sold by another company. For example, a company might manufacture computer parts, which are then used in laptops or desktops sold under a different brand.

Key Points:

- OEMs manufacture parts to meet specifications from another company.

- They often specialize in specific components, improving efficiency and quality.

- OEM manufacturing ensures consistent quality across products.

What Does OEM Stand For in Car Parts

In the automotive industry, OEM parts are components made by the car’s original manufacturer. These are the same parts used when the vehicle was first built.

Key Points:

- OEM car parts guarantee fit and performance.

- They usually come with warranties and meet strict quality standards.

- Using OEM parts helps maintain the vehicle’s value and reliability.

What Does OEM Stand For in Automotive

More broadly in automotive, OEM refers to both vehicles and components made by the original manufacturer. Car brands often rely on OEM suppliers for engines, electronics, and other essential systems.

Key Points:

- OEM automotive parts are designed for specific car models.

- Non-OEM parts are often called aftermarket parts.

- OEM ensures compatibility and safety across vehicle systems.

What Does OEM Stand For in Cars

When talking about cars, OEM highlights authenticity. A car with OEM parts is closer to its original factory specifications, which is important for performance, safety, and resale value.

Key Points:

- OEM car parts match factory specifications exactly.

- They are often preferred by professional mechanics.

- Cars with OEM replacements often have higher resale value.

What Does OEM Stand For in Business

In business, OEM can also refer to companies that design products which other companies sell under their own brand name. This is common in electronics, appliances, and machinery.

Key Points:

- OEM business models reduce production costs for brands.

- They allow companies to focus on marketing and customer service.

- OEM partnerships are essential in global supply chains.

What Does OEM Stand For in Parts

Whether it’s electronics, machinery, or vehicles, OEM parts are original components made by the manufacturer. They are distinct from aftermarket parts, which are made by third-party companies.

Key Points:

- OEM parts provide reliability and quality assurance.

- They ensure proper fit and function.

- Often recommended for critical systems like engines, brakes, or electronics.

What Does OEM Stand For in Aviation

In aviation, OEM refers to parts or components produced by the original aircraft manufacturer. Safety and compliance are paramount in this industry, making OEM parts essential.

Key Points:

- OEM aviation parts comply with strict regulatory standards.

- They help maintain aircraft performance and safety.

- Pilots and airlines prefer OEM components for reliability.

What Does OEM Stand For in Construction

In construction, OEM parts can include machinery, tools, or building materials produced by the original manufacturer. Using OEM ensures compatibility and performance in complex construction projects.

Key Points:

- OEM construction equipment parts last longer and are more reliable.

- They are often certified to meet safety and performance standards.

- Construction companies prefer OEM parts to avoid costly failures.

What Does OEM Stand For in Sales

In sales, OEM often indicates that the product being sold is made by the original manufacturer, not a third-party or generic version. This distinction can affect pricing, warranty, and customer trust.

Key Points:

- OEM products can command higher prices due to quality assurance.

- Sales teams highlight OEM status to build trust.

- Customers associate OEM with reliability and authenticity.

Conclusion

Understanding what OEM means is essential for anyone purchasing products, whether it’s a car part, computer component, or software.

OEM, or Original Equipment Manufacturer, refers to items made by the original producer, ensuring quality, reliability, and compatibility.

Across industries like automotive, technology, and consumer goods, OEM products provide a standard of excellence that aftermarket alternatives may not always match.

While OEM items are often more expensive and less customizable, their benefits—including warranty coverage, perfect fit, and consistent performance—make them a smart choice for consumers who prioritize quality and long-term reliability.

Knowing how to identify OEM products, understanding the differences between OEM and aftermarket, and evaluating your personal needs can help you make informed purchasing decisions.

If you’re buying electronics, upgrading a vehicle, or installing software, choosing OEM can save you from compatibility issues, unexpected failures, and potential safety concerns.

By being informed, you ensure that your investment delivers the best performance and peace of mind.